APLICAÇÃO

| Plate type | Base film | Thickness (mm) |

Hardness (shore A) |

Plate size (mm) |

Main application | Key advantages |

|---|---|---|---|---|---|---|

| Cosmolight® NR | Polyester 0.125mm |

1.14 1.70 2.54 2.84 |

71° 60° 52° 50° |

457×610 610×762 762×1016 |

Envelope Paper/Plastic bag Beverage container Varnish |

Lowest dot-gain and clearer reverse printing Outstanding ink transfer Easy mounting Excellent durability Press-plate ready within one hour |

| Cosmolight® NS | Polyester 0.125mm 0.188mm |

1.14 1.70 2.54 2.84 |

77° 71° 65° 64° |

457×610 610×762 762×1016 |

Paper/Plastic bag Tag & Label Flexible packaging Beverage container |

Lowest dot-gain and clearer reverse printing High resolution and reproduction capability Press-plate ready within one hour Higher Co-solvent ink resistance |

| Cosmolight® NH | Polyester 0.125mm 0.188mm |

1.14 1.70 2.54 2.84 |

81° 76° 71° 70° |

457×610 610×762 762×1016 |

Flexible packaging Tag & Label |

Lowest dot-gain and clearer reverse printing High resolution and reproduction capability Press-plate ready within one hour Higher Co-solvent ink resistance |

| Cosmolight® NEO | Polyester 0.125mm 0.250mm |

1.00 1.14 1.70 2.54 2.84 |

78° 76° 68° 61° 60° |

457×610 610×762 762×1016 |

Tag & Label Envelope Papers Varnish |

Excellent ink transfer Less dot gain and sharper screen image Higher durability Wider latitude of exposure time Easy mounting |

| Cosmolight® CTP QS NEW QH |

Polyester 0.125mm 0.188mm Polyester 0.125mm 0.188mm |

1.14 1.70 1.14 1.70 |

77° 71° 81° 76° |

635×762 762×1016 900×1200 |

Flexible packaging Tag & Label Envelope |

Less plate making time compare to solvent wash plates Durable for water based ink and solvent based ink Processable by existing CTP laser machines |

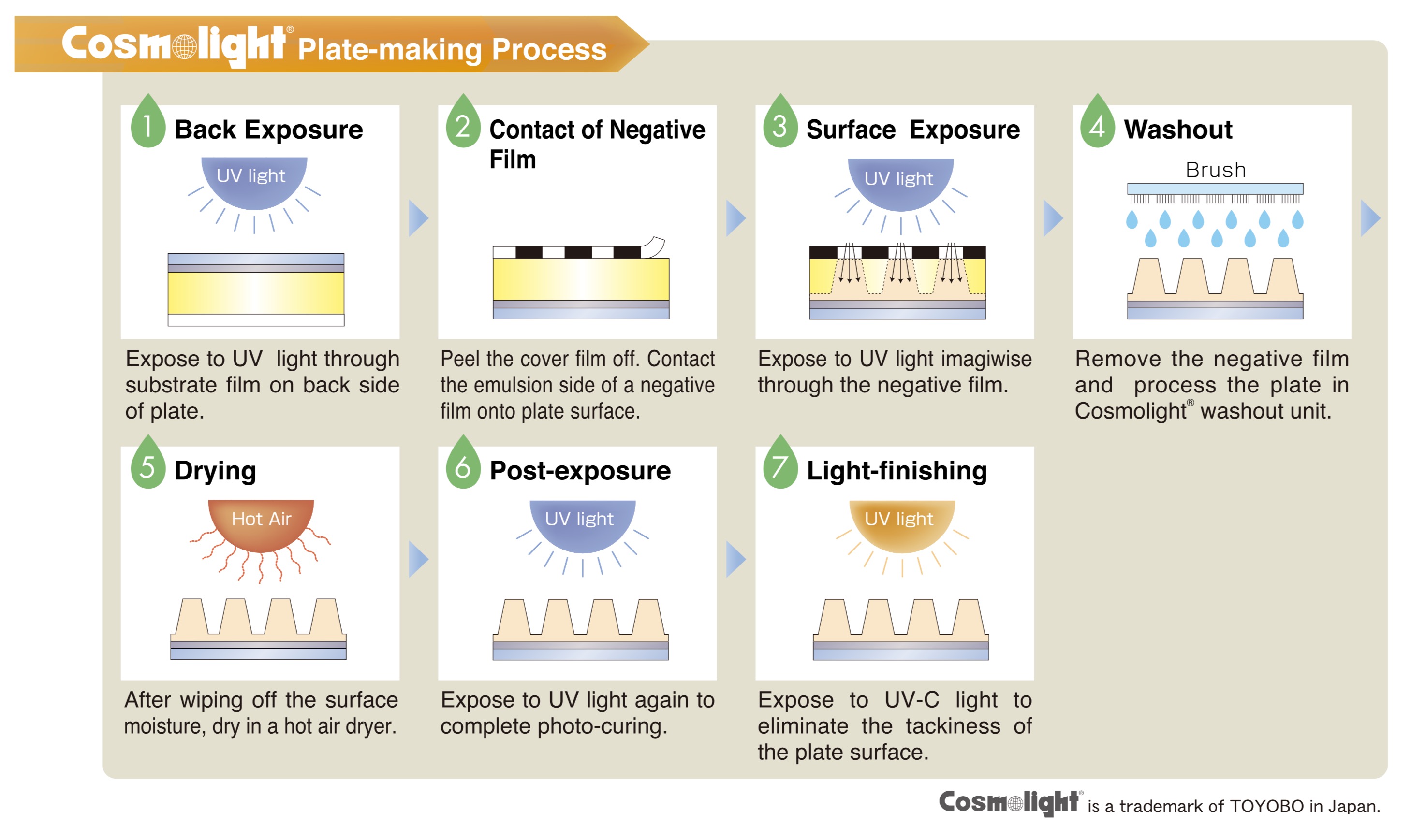

PROCESSAR

VANTAGENS

TOYOBO comercializou a primeira chapa flexo* processada a água do mundo.

*processadas em água e sem solventesLíder Mundial na tecnologia de fotopolímeros, produziu uma chapa processada a água que pode ser utilizada tanto com tintas UV como com tintas base água ou base álcool.

Washout in plain tap water with a small amount of mild detergent.

Eliminates the use of dangerous hydrocarbon and hazardous washout solvents.

Plates are "press-ready" within an hour and "press-down time" is dramatically reduced.

Print quality is excellent with both water-based and alcohol-based ink.

High resolution and reproducibility provides sharp details.

Excellent ozone resistance.

Excellent ink transfer.

Excellent resistance to solvent ink. (type NS, NH, QS and QH)

Thickness tolerance allows for "kiss" impression settings.

"A closed washout system" allows for repeated use of the washout solution.

PROPRIEDADES

| Plate type | Image reproduction |

Fine line |

Isolated dots |

Thickness tolerance |

Resistance to ink |

||||

|---|---|---|---|---|---|---|---|---|---|

| Water | Alcohol | Solvent | UV flexo | Oil base | |||||

| Cosmolight® NR | 175LPI 1–95% |

0.03mm | 0.10mm | 0.02mm | Excellent | Excellent | Fair | Good | Poor |

| Cosmolight® NS | 175LPI 1–95% |

0.03mm | 0.10mm | Excellent | Excellent | Good | Good | Poor | |

| Cosmolight® NH | 175LPI 1–95% |

0.03mm | 0.10mm | Excellent | Excellent | Good | Good | Poor | |

| Cosmolight® NEO | 150LPI 2–95% |

0.05mm |

0.15mm | Excellent | Excellent | Poor | Good | Poor | |

| Cosmolight® CTP QS NEW QH |

200LPI 1–95% 200LPI 1–95% |

0.03mm 0.03mm |

0.10mm 0.10mm |

Excellent Excellent |

Excellent Excellent |

Good Good |

Good Good |

Poor Poor |

|